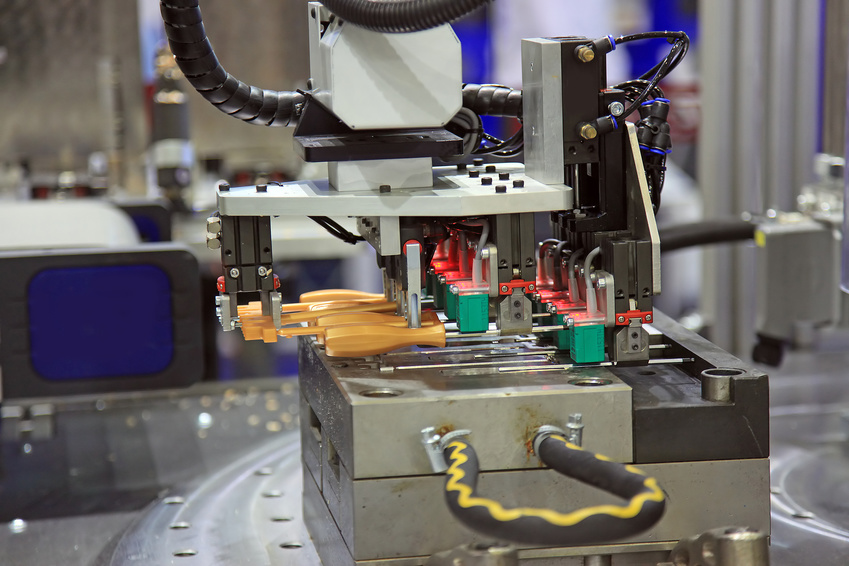

Plastic injection molding products suppliers are typically involved in a variety of different industries such as car parts, thermoplastics, and 3D printing. Plastic is already a multi-billion dollar industry, as the $373 billion in goods delivered by plastics manufacturers in 2012 alone already shows, but those doing the plastic injection molding have even more reason for optimism.

Plastic injection molding products suppliers are typically involved in a variety of different industries such as car parts, thermoplastics, and 3D printing. Plastic is already a multi-billion dollar industry, as the $373 billion in goods delivered by plastics manufacturers in 2012 alone already shows, but those doing the plastic injection molding have even more reason for optimism.

According to a new report by Allied Market Research titled, the future is bright in the world of plastic injection molding manufacturers. The report estimates that the plastic injection molding market will increase by a compound annual growth rate (CAGR) of 4.9% from 2015 to 2020. By the turn of the decade, the total market is expected to be worth $162 billion.

As the report’s abstract points out, the world of plastic injection molding injection is divided up amongst regions, including North America, Europe, Asia-Pacific, and LAMEA.

“In 2014, North America was the leading market for injection molded plastic, accounting for around 35% of the global market share,” the summary reads. “Asia-Pacific and LAMEA have witnessed large-scale demand for injection molded plastic on account of its growing demand in building and construction sector, consumer appliances, and automotive industries. Hence, Asia-Pacific is expected to grow at a CAGR of 6.8% during 2014–2020.”

While the industry is projected to do slightly better percentage wise overseas, plenty will still be done right here on U.S. soil. Today, the industry currently employs about 900,000 people in the U.S. alone. In fact, the plastics industry is the third-largest manufacturing industry in the country.

As more and more companies use plastic to innovate and improve their own products, industry growth is opening doors for even more innovation to be done in the injection molding industry itself, creating a mutually beneficial cycle. Industries like automotive, packaging, electronics and consumer goods, building and construction, and medical disposal have seen steady increases in their dependency on these products.

If you’re already utilizing these kinds of products, you’re on the cutting edge of technology. If not, your company may need to get with the times.