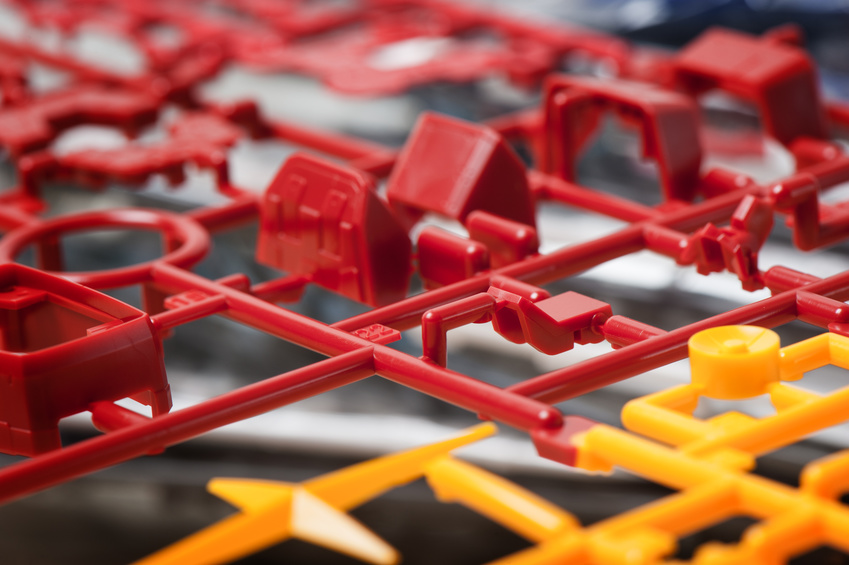

We could tell you that custom plastic injection molding is less complicated than it sounds, but that’s not entirely true (or even partly true). But when you work with a proven plastic injection molding company with experience in your industry, you can ensure the manufacturing process proceeds seamlessly. Most Americans have little understanding of how plastics are manufactured, even though we use plastic products every day of our lives. We brush our teeth with plastic toothbrushes, we drink liquid in plastic bottles, we use plastic medicine bottles for our afternoon headache, and virtually every other aspect of our daily lives.

We could tell you that custom plastic injection molding is less complicated than it sounds, but that’s not entirely true (or even partly true). But when you work with a proven plastic injection molding company with experience in your industry, you can ensure the manufacturing process proceeds seamlessly. Most Americans have little understanding of how plastics are manufactured, even though we use plastic products every day of our lives. We brush our teeth with plastic toothbrushes, we drink liquid in plastic bottles, we use plastic medicine bottles for our afternoon headache, and virtually every other aspect of our daily lives.

Have any questions about the plastic injection molding process? We’ve got you covered…

How does plastic injection molding work exactly?

You could fill a very long, very detailed book with this information. But in short, the process starts with a team of skilled industrial or packaging engineers designing a custom mold. The client approves the design or supplies their own. Then, various types of plastics materials are heated and forced into the mold. Unique branding or printing can also be included in the finished design.

Why are plastics the preferred material for pharmaceutical containers, food packaging containers, and more?

Consistency. The best plastic injection molding suppliers can produce near unlimited quantities of containers, closures, and other plastic goods with a very high rate of consistency. Not only that, but most plastics are highly recyclable and relatively cheap compared to metal, paper products, or glass. Finally, plastics offer a number of preservative benefits.

Why should I work with plastic injection molding manufacturers in the United States?

In a study from IndustryWeek, fully 70% of manufacturers cited better skilled talent as a reason for moving operations to the United States. That’s four times the number who cited skilled talent as their reason for moving offshore. There are nearly 16,000 molding and plastic facilities in the country employing 900,000 skilled workers. Working with an American plastic injection molding company ensures the highest quality products.

Can molds be custom made for my needs?

Absolutely. Thanks to advances in 3D imaging technology, it’s never been easier to work with inventors and clients to design custom plastic solutions for their unique needs.

What about custom printing and colors?

Custom plastic injection molding can be tailored to your exact needs, including unique colors, branding, and high-tech printing options.

Do you have any more questions about the injection molding process? Let us know in the comments!